Call Us Today/WhatsAPP

(+86)-138-128-59969

Views: 0 Author: MEPER MACHINE Publish Time: 2023-03-17 Origin: MEPER MACHINE

What a Coex blow molding machine?

The Coex blow molding machine is a type of manufacturing equipment used to create multilayer plastic products,such as sunscreen bottles,ketchup bottle and so on. This technology involves the use of multiple layers of plastic materials PE,EVOH,Adhesive to produce bottles that are oxygen-proof, UV-proof, breakage-proof, lightweight, and recyclable. In this article, we will discuss the benefits of using a Coex blow molding machine to produce ketchup bottles and how it can improve the efficiency and quality of your manufacturing process.

How the coex blow molding machine is used to produce ketchup bottles?

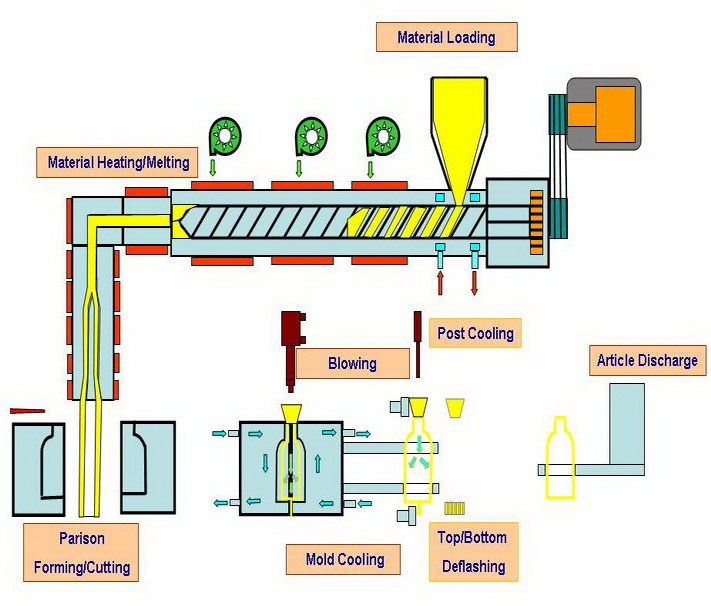

The Coex blow molding machine is used to produce ketchup bottles through a process that involves the following steps:

The first step in the blow molding process is to prepare the raw materials. The plastic materials used in Coex blow molding technology are usually high-density polyethylene (HDPE), ethylene-vinyl alcohol (EVOH), and adhesive.

Extrusion:

Once the raw materials have been prepared, they are fed into each hopper of the extrusion blow molding machine. During the extrusion process ,the plastic material are melted ,then across the screw,they are extruded as a hollow tube out of the die head. We usually call it parison.

Molding:

The parison is clamped into a mould, it is formed by injecting air pressure with a blow pin and pressing it against the wall of the ketchup bottle mould.The air pressure is maintained until the bottle has cooled and hardened, at which point it is ejected from the mold.

Coex Layering:

In the Coex blow molding machine, the ketchup bottle is produced with multiple layers of plastic materials(hdpe,evoh,adhesive). The material is extruded proportionally by different screws , and the proportions of each layer can be customized depending on the desired properties of the bottle. For example, a ketchup bottle may be created with a layer of virgin HDPE, followed by a layer of adhesive, a layer of EVOH, another layer of adhesive, and then another layer of virgin HDPE.

Raw material ratio is shown below

1. 3 layer Coex: Virgin HDPE/adhesive/EVOH

95% /5% /5%

2. 5 layer Coex: Virgin HDPE/Adhesive/EVOH/Adhesive/Virgin HDPE

42.5% /5% /5% /5% /42.5%

3. 6 layer Coex: Virgin HDPE/Recycled HDPE/Adhesive/EVOH/Adhesive/Virgin HDPE:

20% /45% /5% /5% /5% /20%

Finish products

After the bottle has been molded, it is trimmed and finished to remove any deflashing parts material and create a smooth, polished surface. The finished ketchup bottle is then ready for filling and distribution.

The different types of Coex blow molding machines and their advantages

Usually do food packaging bottle multilayer machine has 3 layers, 4 layers 5 layers of extrusion blow molding machine.

The Coex technology used in multi-layer extrusion blow molding machines.There are several advantages when producing plastic bottles. Based on cost, transportation and other factors,plastic bottles is better to replace traditional glass and metal cans. Here are some of the key advantages of using a multi-layer extrusion blow molding machine:

Lightweight:

Multi-layer extrusion blow molding machines can produce plastic bottles that are lighter than glass and metal cans. It makes them easier to shipping, as well as more cost-effective.

Breakage-proof:

Plastic bottles produced using multi-layer extrusion blow molding machines are also much less broken than glass and metal cans. This makes them a safer option for both manufacturers and consumers, as well as reducing the risk of costly damage during shipment.

Recyclable:

Another advantage of using co extrusion blow molding machines is that the recycled plastic material can be used in the multilayer bottles. This not only saves the cost of raw materials, but also reduces the environmental pollution caused by the excessive use of plastics.

Coex technology:

The Coex technology used in multi-layer extrusion blow molding machines provides an added layer of protection of the bottle. This is achieved by using multiple layers of plastic with different properties to provide a barrier against external factors such as UV light and oxygen. This ensures that the contents of the bottle remain fresh for a longer period of time, making them ideal for products that have a long shelf-life.

Choosing the right coex blow molding machine.MEPER MACHINE

MEPER MACHINE specializes in the production of multi-layer blow molding machines for years,we are the top coex blow molding machine in China.

Choosing the right Coex blow molding machine for ketchup bottle production requires careful consideration of various factors, including production volume and materials used. In the production process of multi-layer blow molding machine, the precision of die head and screw is very important. These parts are researched and produced by MEPER MACHINE. Making the right choice in selecting a Coex blow molding machine is crucial to ensuring efficient and high-quality ketchup bottle production.

|  |

Using a Coex blow molding machine for ketchup bottle production offers many advantages,that plastic multilayer bottles are lightweight, breakage-proof, and suitable for long-distance transportation. The plastic material used in production is also recyclable, making it an environmentally-friendly choice. Coex technology allows for the production of bottles with multiple layers, providing improved durability and product protection against oxygen, ultraviolet rays, and other external factors. The ability to customize bottle shapes and sizes, along with high production capacity, makes Coex blow molding machines an efficient and cost-effective option for ketchup bottle production.