Call Us Today/WhatsAPP

(+86)-138-128-59969

Views: 0 Author: Site Editor Publish Time: 2023-06-02 Origin: Site

Cracking the Code: Discover the Best Blow Molding Machine Classification for Your Business

Unlocking the Potential: Explore Blow Molding Machine Classifications for Your Business. Discover the diverse categories, transmission modes, workstations, designs, and applications available. From processing capabilities to drive options, we'll navigate the world of blow molding machines together. Get ready to delve into the exciting realm of classification and find the perfect fit for your manufacturing needs. Let's embark on this journey of exploration and unlock the possibilities!

I Classification according to maximum product volume

MEPER blow molding machines are categorized based on their maximum product volume: 2L, 5L, and 10L.Let's explore the applications for each category:

2L Blow Molding Machines:

Suitable for small to medium-sized products, typically ranging from 50ml to 2 liters.

Applications: Cosmetics containers (e.g., 100ml shampoo bottles), personal care bottles (e.g., 500ml body lotion bottles), single-serve beverage bottles (e.g., 250ml milk bottles).

5L Blow Molding Machines:

Ideal for medium-sized products, typically ranging from 2 to 5 liters.

Applications: Household items (e.g., 4L storage containers), automotive parts (e.g., 4L engine oil bottle), medium-sized liquid dispensers (e.g., 5L detergent bottles).

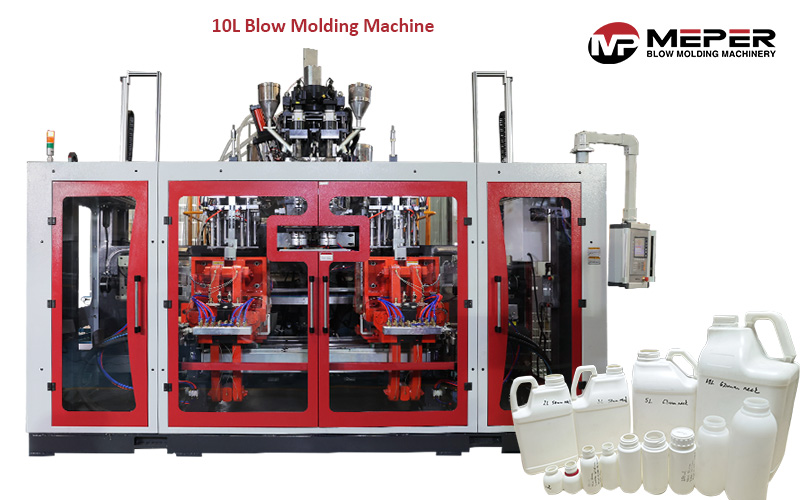

10L Blow Molding Machines:

Designed for larger products and industrial applications, typically ranging from 5 to 10 liters.

Applications: Chemical drums (e.g., 10L chemical containers),agrochemical bottles (e.g., 8L fertilizer containers), large water storage containers (e.g., 7L water jugs).

Consider the specific product volume and size requirements of your industry when choosing the appropriate blow molding machine category. MEPER machines offer reliable performance and precise production capabilities to meet your specific needs.

II Classification Based on Drive Mode

Blow molding machines can be classified into two main types based on their drive mode: hydraulic and electric. Understanding the operational principles and benefits of each drive mode is crucial when selecting the right machine for your business.

1.Hydraulic Blow Molding Machines:

Hydraulic machines utilize hydraulic power systems to operate the various functions of the blow molding process. These machines offer the following advantages:

Excellent clamping force for handling larger and more complex molds.

High production efficiency and fast cycle times.

Suitable for a wide range of materials, including HDPE, LDPE, and PP.

Notable brands for hydraulic blow molding machines include:

MEPER Machine (e.g., MEPER-MP70FS) https://mepermachine.com/

Jomar Corporation (e.g., Jomar Hydraulic Machines) https://jomarcorp.com/

Sidel Group (e.g., SBO Universal) https://www.sidel.com/en

2.Electric Blow Molding Machines:

Electric machines employ electric motors and servo systems for precise control and energy efficiency. They offer the following benefits:

Lower energy consumption and reduced operating costs.

Enhanced accuracy and repeatability in the production process.

Quieter operation and lower environmental impact.

Notable brands for electric blow molding machines include:

Kautex Maschinenbau (e.g., KBB series) https://www.kautex-group.com/

Nissei ASB Machine Co., Ltd. (e.g., ASB-70DPH/DB) https://www.nisseiasb.co.jp/

By understanding the operational principles and advantages of hydraulic and electric blow molding machines, you can make an informed decision when selecting a machine that best suits your production requirements.

III Classification Based on single station and double station

Extrusion blow molding machines can also be categorized based on the number of workstations: single-station and double-station. Understanding the advantages and considerations of each type will help you choose the appropriate workstation configuration for your specific needs.

Single-station machines have one mold and one workstation, where the entire blow molding process takes place. Double-station machines feature two workstations with separate molds, allowing simultaneous production and shorter cycle times.

When the screw is the same, in principle, the output of the double station is 2 times the output of the single station blow molding machine. Single station blow molding machines have lower initial investment and maintenance costs than two-station machines. But considering the demand for increased output in the future, the double station blowing machine is more cost-effective. MEPER MACHINE Through many years of production experience, our customers will generally choose the double station blow molding machine.

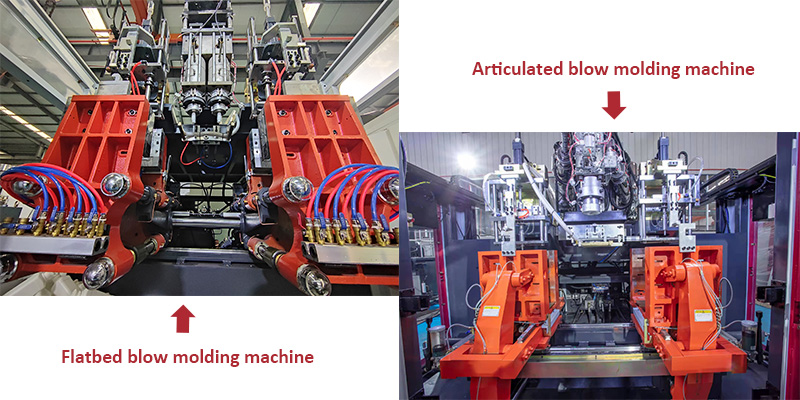

IV. Characteristics of Flatbed and Articulated Blow Molding Machines

In the world of blow molding machines, there are two primary types based on the design of their mold carriage system: flatbed and articulated arm.

Flatbed blow molding machines feature a stationary mold mounted on a horizontal platform. The blow molding machines are highly versatile, capable of producing a wide range of products with varying shapes and sizes.They offer easy access to the mold, simplifying maintenance and mold changes.

Articulated blow molding machines offer superior advantages in manufacturing. Their unique design ensures high-quality plastic products. Key features include:

Strong Clamping Force: Curved arms provide optimal mold closure, resulting in uniform wall thickness and reduced flash formation. Smooth mold closing ensures impeccable product quality.

Stability and Durability: The single-piece iron plate chassis ensures stability, minimizing vibrations for consistent performance.

Wide Mold Opening: Curved arm machines accommodate wide-bodied containers like jars and buckets.

Precise Power Transmission: Sliders and rails enable precise mold positioning and synchronization, ensuring consistent product quality.

When choosing between flatbed and articulated blow molding machines, consider factors such as the size and complexity of your products, production volume, available floor space, and specific industry requirements. By understanding the distinctive characteristics of each type, you can make an informed decision that aligns with your production goals.

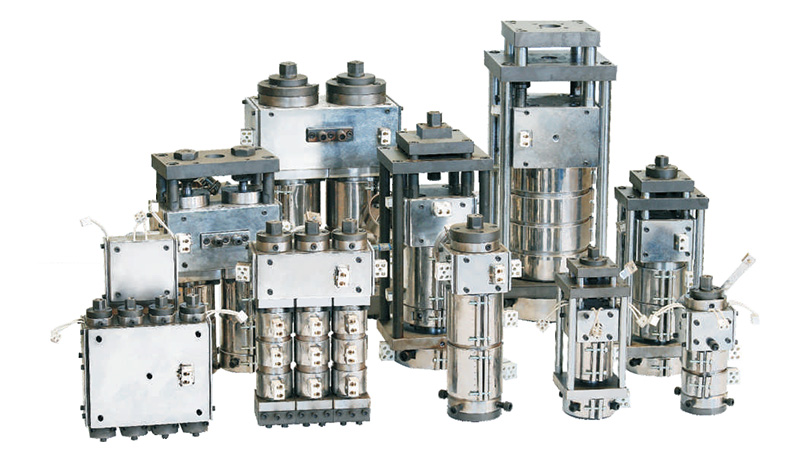

V. Characteristics of Blow Molding Machines Based on Mold and Screw Configurations

Blow molding machines can be classified based on the number of molds and screws they possess. Let's explore the characteristics and considerations of different configurations:

Mold Configuration:

a) Single-head Blow Molding Machines:

Characteristics: These machines have a single mold for producing one product at a time.

Advantages: Ideal for small to medium production volumes and simpler product designs.

Considerations: Longer cycle times compared to multi-head machines, suitable for lower production rates.

b) Multi-head Blow Molding Machines (2, 3, 4, 6 heads):

Characteristics: These machines feature multiple molds that enable simultaneous production of multiple products.

Advantages: Increased production efficiency and higher output rates compared to single-head machines.

Considerations: Suitable for larger production volumes and complex product designs, require precise synchronization of mold movements.

Screw Configuration:

a) Single-layer Blow Molding Machines:

These machines have a single screw and are used for producing single-layer products.

b) Multi-layer Blow Molding Machines (2, 4, 6 layers, and view line layer):

These machines feature multiple screws and are capable of producing multi-layer products.Enables the production of multi-layer containers with enhanced properties, such as barrier properties and visual appeal.

The blow molding machine requires precise control of layer thickness and material distribution, suitable for applications requiring specific layer arrangements.

When selecting a blow molding machine based on mold and screw configurations, consider factors such as your product requirements, production volume, material compatibility, and desired product properties.

VI. Classification Based on Application

MEPER MACHINE can be classified based on its application. Let's explore the advantages of each category:

Engine Oil Bottles:

Advantages: Blow molding machines for engine oil bottles offer precise control over bottle dimensions, ensuring compatibility with engine oil packaging requirements. The machines provide high-speed production capabilities and consistent bottle quality.

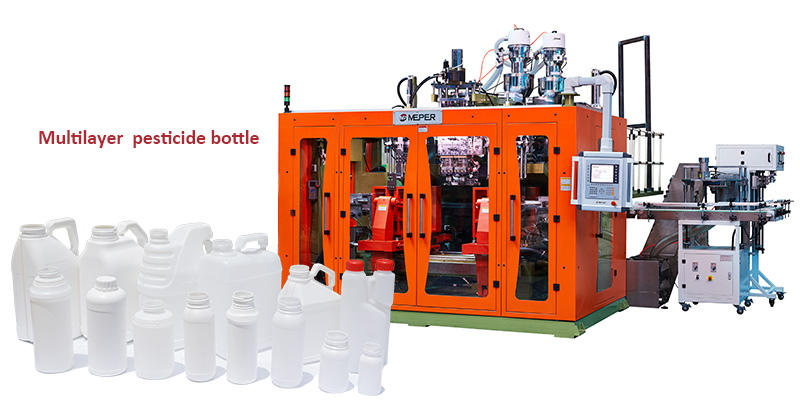

Multi-layer Pesticide Bottles:

Advantages: Blow molding machines for multi-layer pesticide bottles enable the production of containers with excellent barrier properties, protecting the contents from moisture, light, and external factors. This ensures the efficacy and safety of the pesticides.

Personal Care Packaging Bottles:

Advantages: Blow molding machines for personal care packaging bottles provide versatility in design, allowing for various shapes and sizes. They offer efficient production rates and ensure the durability and aesthetics of the packaging.

Milk Bottles and PETG Bottles:

Advantages: Blow molding machines for milk bottles and PETG bottles offer hygienic and safe packaging solutions. They provide excellent clarity, impact resistance, and durability. These machines ensure the precise formation of bottle necks and handles for easy handling.

Other Applications:

Advantages: MEPER MACHINE offers versatile blow molding solutions for a wide range of applications beyond the mentioned categories. Whether it's packaging for beverages, household products, automotive components, or custom containers, the machines deliver reliable performance, flexibility, and consistent quality.

By selecting the appropriate blow molding machine based on the desired application and material storage capacity, you can optimize production efficiency, product quality, and meet specific industry requirements. Explore the possibilities with MEPER MACHINE to enhance your packaging solutions.

VII. Purchasing a Blow Molding Machine: The Process and Contacting MEPER MACHINE

When it comes to purchasing a blow molding machine from MEPER MACHINE, we prioritize a seamless and efficient communication process. Here's an overview of the steps involved:

Initial Consultation: Contact our team to discuss your specific requirements, including production volume, product specifications, and budget considerations. We will provide personalized recommendations based on your needs.

Machine Selection: Our experts will guide you through the various machine categories, helping you choose the most suitable model for your application. We'll consider factors such as product volume, material, and desired features.

Customization Options: If necessary, we offer customization services to tailor the blow molding machine to your unique requirements. This may include modifications to the machine's configuration, automation level, or additional features.

Quotation and Contract: Once the specifications are finalized, we will provide you with a detailed quotation, outlining the cost, delivery timeline, and warranty terms. Upon agreement, we proceed to finalize the purchase contract.

Production and Delivery: Our experienced team will commence the production process, ensuring strict quality control measures at every stage. We prioritize timely delivery and offer logistics support to ensure your machine arrives safely.

Installation and Training: MEPER MACHINE provides comprehensive installation guidance and training for your operators to ensure they are proficient in operating and maintaining the equipment.

After-Sales Support: We stand by the quality of our machines and offer prompt after-sales support, including technical assistance, spare parts availability, and maintenance services.

To start the process or for any inquiries, please reach out to us via WhatsApp 0086 13812859969. Our dedicated team is ready to assist you in choosing the right blow molding machine and optimizing your production capabilities. Join the list of satisfied customers who have benefited from MEPER MACHINE's expertise and reliable solutions.

Take your blow molding operations to the next level. Contact us today and let MEPER MACHINE be your trusted partner in achieving manufacturing excellence.